Don’t let maintenance overwhelm your water leak detection system!

Use Patented Dust-Resistant Water Leak Sense Cables from TTK

Are you experiencing repetitive nuisance alarms?

After a few years of use, it’s not uncommon for water leak detection cables to release alarms without the presence of water. Some manufacturers might say that “The cable has probably become contaminated from dust over time. Sometimes the cable can be cleaned, sometimes a replacement is required.”

The “nuisance alarms” can disrupt the normal site monitoring, or, worse still, can leave the real leaks undetected and therefore the site without protection. After repeated false alarms, the system is often considered to be “unreliable” or even a “nuisance” and is then unplugged. It’s usually only after this event that real disasters occur.

However, these scenarios could be avoided with dust-resistant water leak sense cables from TTK, the first of their kind on the market.

A conventional water sensing cable installed in a dusty environment experiencing a dust-caused "false alarm"

What are “false alarms” and how do they occur?

What facility managers commonly call “false alarms” are when disturbed water sense cables release leak alarms without the presence of water. This is often the case in an environment where dust is commonly present. However, it may also occur in a neat environment where metal surfaces - such as earthing braids, raise floor pedestals, or edges of cable trays – are present in zones where cables are installed.

On a sense cable, a leak is detected when electrical contact is created between two sensing wires. Any conductive material that is able to create a contact would trigger a leak alarm on the system. These materials include conductive dust and any grounded metal part under the raised floor, as they are all in contact through the building’s foundations. That’s how false alarms occur.

How can the TTK water sense cable efficiently resist dust?

- The main reason is the cable structure.

Let’s compare the structure of a classic water sense cable and that of a dust-resistant sense cable.

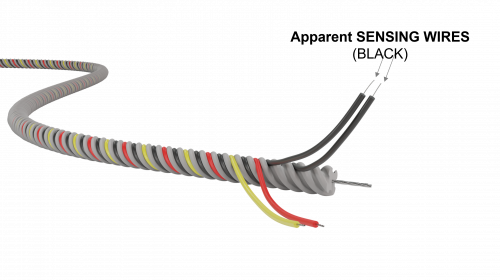

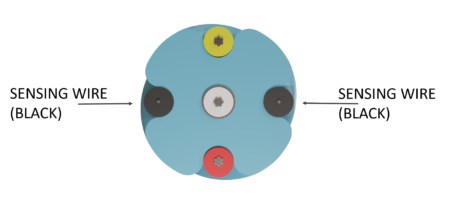

"Conventional” water sensing cable:

On a “conventional” water sense cable, there are two sensing wires (black):

- Carbon-coated wires for liquid absorption.

- Both conductive spiraling sensing wires apparent from the cable surface.

TTK dust-resistant water sensing cable:

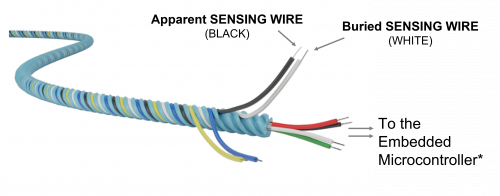

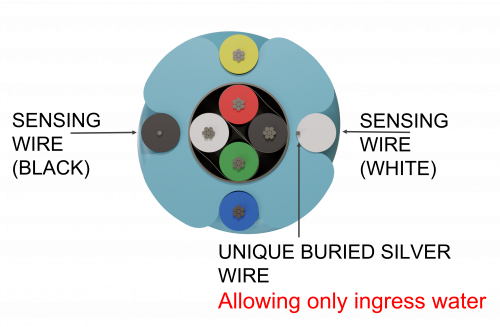

TTK reinvents 2-wire detection:

- 1 black wire is the classic carbon-coated wire for liquid absorption.

- 1 unique buried silver wire allowing only ingress water, covered by the second sensing wire.

This ingenious cable structure – design patented in France as well as in many other countries - allows the cable to sense only ingress water, and not to be disturbed by the presence of dust and all kinds of conductive residue from the environment that has accumulated on the cable surface; thus, efficiently preventing contamination alarms.

*: The four wires inside the cable core allow the embedded microcontroller to be powered and assure a continuous communication with the monitoring panels without the need for any intermediary panels. (For more information about the microcontroller, please ref to the article "SMART WATER LEAK SENSE CABLE")

- An embedded microcontroller provides supplementary protection.

With an embedded microcontroller, the TTK water sense cable becomes digital. Each individual cable (maximum standard length 15 m/49 ft) is designed to be independent and tolerates a level of pollution that does not affect its performance. Compared with using an analog cable (water cable without a microcontroller) there is no accumulation of pollution on the cable. That’s why it is not necessary to carry out preventive cleaning on installed TTK sense cables.

Conclusion: The TTK water sense dust-resistant cable requires minimum maintenance and has a long installation life

Thanks to the unique and patented cable structure, the TTK water sense cable can efficiently prevent false alarms that have been triggered by dust, condensation and metal parts. It can therefore be installed near the risk source to ensure a very early detection, without worrying about any ambiguous alarms!