TTK Project Case Study: TTK in City Centre Mirdif, UAE

TTK FUEL LEAK DETECTION SYSTEM IN CITY CENTRE MIRDIF, UAE

To read this case study in printable PDF format.

Project Background

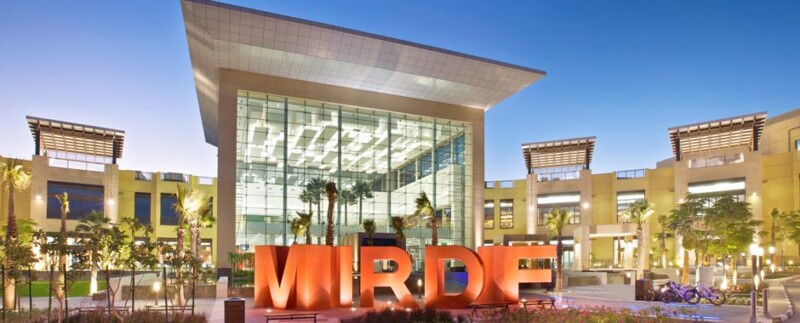

City Centre Mirdif is a shopping mall in the residential area of Mirdif, in Dubai, United Arab Emirates. It opened on 26 March 2010 and has a gross leasable area of 196,000 m² and houses 465 retail stores.

Project requirements

In this hyper-scale shopping mall, several diesel-powered engine generators provide emergency power in the event of a loss of station service power.

However, if any fuel/diesel leaks go undetected in generator rooms and prevent generators from working, the shopping mall would still be forced to close. That’s why the end-user requested TTK to supply a reliable liquid leak detection system to monitor the generators and their auxiliary equipment (day tank, pipes) 24/7, to ensure uninterrupted functionality of the whole system.

Areas to be protected

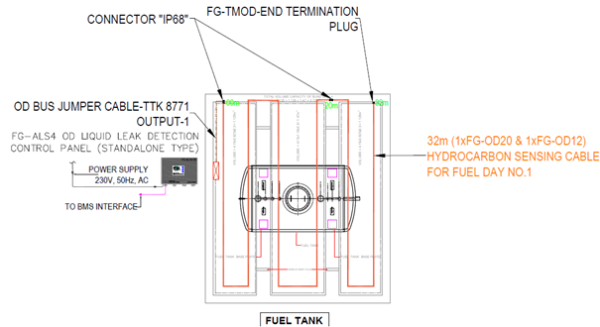

The scope of fuel leak detection work for the Mirdif shopping mall is to protect seven day-tanks which fuel generators located in different generator rooms.

TTK's Solution

For this project, TTK ME recommended its fuel leak detection system, using FG-ALS4-OD leak detection control panels and FG-OD fuel sensing cables in different lengths.

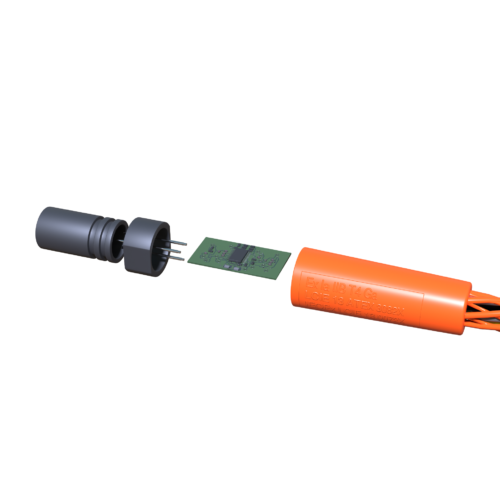

Sense cable

- Insensitive to water (as are all TTK oil sensors), the FG-OD cables detect the presence of liquid hydrocarbon at any point along their length. They were installed in the generator rooms, near leak sources in this project.

- Technical advantages of TTK’s hydrocarbon sensing cable:

• Detects quickly, even small quantities of hydrocarbon liquid, allowing to give very early alarm and gain precious time for operators to react in the event of a leak.

• Reusable, allowing onsite testing and significantly reducing equipment cost.

• Every individual cable is addressable and independent, allowing the detection and location of multiple leaks in the same circuit.

|

Addressable Oil Sensing Cable: |

Embedded microcontroller |

Monitoring panel

- To monitor all sensing cables, a multiple-zone alarm & locating panel (reference name FG-ALS4-OD) was installed in the generator rooms.

- Equipped with a touch screen, relays and RS485 Modbus serial link interface, the panel works as a stand-alone system and monitors up to four independent zones and pinpoints the location of leaks.

- In the event of a liquid leak or default on the sense cables for each zone, the responses from the FG-ALS4-OD alarm & locating unit:

• An audible alarm is triggered and a relay is activated.

• The touch screen of the panel displays the zone, the location of the leak (on the cable) and details of the fault (the type of fault leak or cable break).

• Report to the DCS/SCADA/Safeguarding system via a JBUS/MODBUS protocol.

Four Zones Alarm & Locating System Unit

for Hydrocarbon Leak Detection (FG-ALS4-OD) installed on site

Schema of installation of TTK oil fuel leak detection

monitoring panel for day tank